Metal processing refers to the production activities of processing materials with metal elements or mainly composed of metal elements. Metal processing methods and techniques include:

casting

Casting: Metal is heated to melt and then poured into a mold, suitable for machining complex parts.

Pouring classification

Sand casting: low cost, small batch, can process complex modeling, but may require a lot of post-processing processes.

Investment casting/loss of wax casting: This process has a high degree of continuity and accuracy, and can also be used for complex molding. It is under the premise of relatively low processing cost, can achieve very surface effect, suitable for mass production.

Injection casting method: used for processing complex molding with high error. Due to the characteristics of the process itself, the product does not need post-processing after molding, however, only in the case of mass production can show the advantage of low cost. Die casting: high processing costs, only in the case of mass production costs are reasonable. But the cost of the final product is relatively low and the error is relatively high. It can be used to produce thin wall parts.

Spin casting: Ideal for machining small parts, usually used in jewelry. Rubber models can be used to reduce the cost of machining.

Directional solidification, the machine can produce good fatigue resistance performance of the very strong heat-resistant alloy pouring into the model, and then through strict control of heating and cooling process, to eliminate any small flaws Plastic forming part of the plastic forming: refers to the forming of metal heating with to modelling, belongs to the labor-intensive production.

Plastic forming

Forging: it is one of the simplest and oldest metal molding techniques to shape metal by hammering and extruding under the condition of cold working or high temperature operation.

Bunching: The high-temperature metal slab passes through a series of cylindrical rollers, which press the metal into the mould to obtain a preset shape.

Wire drawing: The process of drawing metal strips into fine filaments using a series of drawing dies of progressively smaller sizes.

Extrusion: An inexpensive continuous process of forming solid or hollow metal with the same cross-sectional shape for both high temperature and cold work.

Impact extrusion: Process for machining small to medium size parts without taper requirements. Production is fast, can process all kinds of wall thickness parts, processing cost is low.

Powder metallurgy: A process for processing ferrous and non-ferrous metal components. There are two basic processes: mixing the alloy powder and pressing the mixture into the mold. Metal particles are heated and sintered at high temperature. The process does not require machine work, the raw material efficiency is up to 97%, and different metal powders can be used to fill different parts of the mold.

Solid forming

Solid forming processing: refers to the use of raw materials are some at room temperature conditions can be molded metal strips, pieces and other solid form. Belong to labor intensive production. Processing cost input can be relatively low.

Solid forming processing classification

Spinning: A very common process used to produce circular symmetrical parts, such as plates, cups, and cones. In machining, the high-speed rotating sheet metal is pushed into the same high-speed rotating, fixed lathe model to obtain a predetermined shape. The process is suitable for all kinds of batch production.

Bending: An economical manufacturing process for any form of sheet, rod, or tubular material.

Continuous tie forming: feed the metal sheet between the pressing rollers to obtain a continuous length of metal shape with consistent cross section. Similar to the extrusion process, but there is a limit to the wall thickness of the processing components, only a single wall thickness can be obtained. Only in the premise of mass production, processing costs are most reasonable.

Stamping molding: metal sheet placed between the male mold and the female mold after pressing molding, used for processing hollow modeling, depth can be deep or shallow.

Punching: the process of punching and cutting a certain shape on the metal sheet with special tools, which can be applied to large and small batch production.

Punching: similar to the punching process, the difference is that the former uses the punching part, while the latter uses the rest of the metal sheet after punching.

Cut: Cutting a piece of metal in the same way as cutting paper from the best position with a pair of scissors.

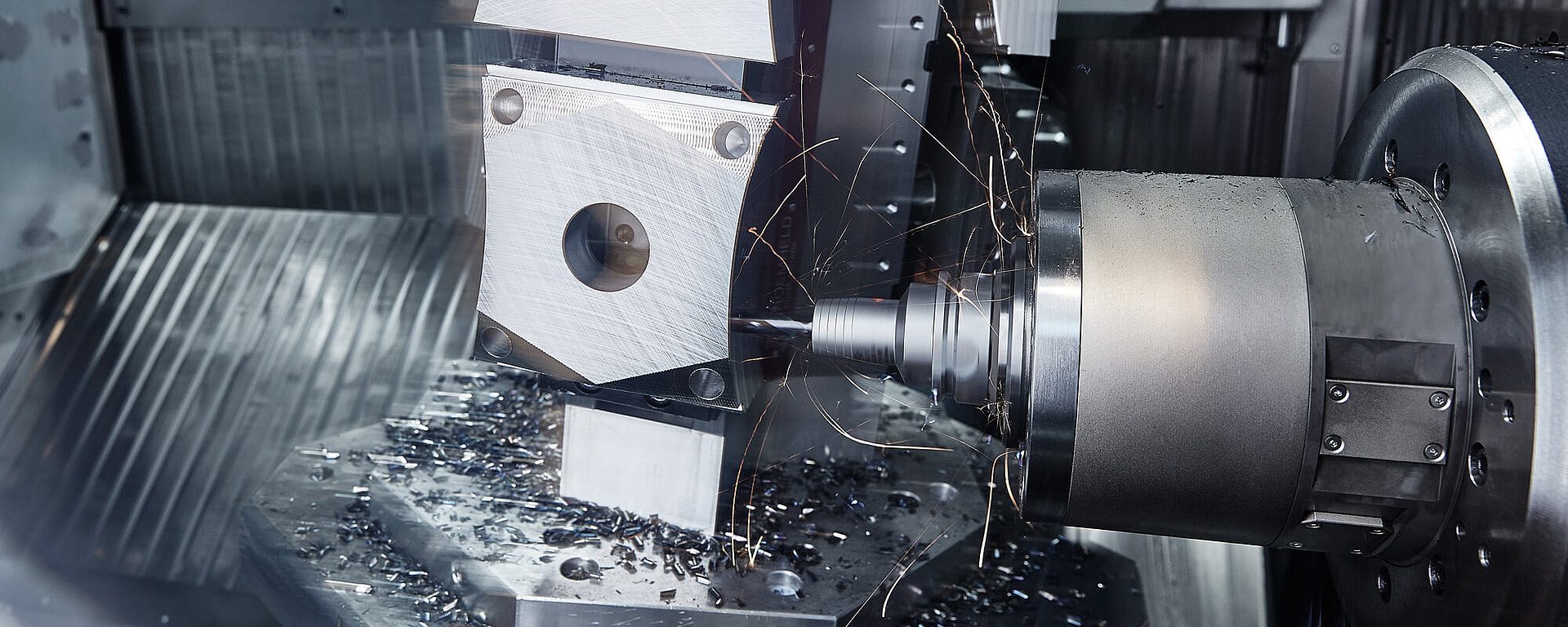

Chip forming: when the metal is cut, the cutting method of chip production is collectively referred to as chip forming, including milling, drilling, lathe processing and grinding, sawing and other processes.

No chip forming: the use of existing metal strip or metal sheet, etc. No chips are produced. These processes include chemical machining, corrosion, discharge machining, sand blasting, laser cutting, water jet cutting and thermal cutting.

Wire drawing

Drawing can be made according to decoration needs, straight lines, disorderly lines, thread, ripple and spiral lines.

Straight line drawing refers to the process of straight lines on the surface of aluminum plate by means of mechanical friction. It has the dual function of brushing away scratches on the surface of aluminum plate and decorating the surface of aluminum plate. Straight lines have continuous lines and intermittent lines, continuous lines can be used by 100 clean cloth or stainless steel brush through the surface of the aluminum plate for continuous horizontal linear friction (such as manual grinding under the condition of the current device or with a planer clamp steel wire brush on the aluminum plate). Change the steel wire diameter of the stainless steel brush, can obtain different thickness of the grain. Intermittent silk lines are generally processed by brushing machine or rubbing machine.

Making principle: two groups of differential wheels rotating in the same direction, the upper group is the fast rotating roller, the lower group is the slow rotating rubber roller, aluminum or aluminum alloy plate through the two groups of roller wheels, is brushed out fine intermittent straight lines.

Random drawing is a kind of irregular, no obvious lines of matte silk obtained by moving the aluminum plate around and rubbing with the copper wire brush running at high speed. This kind of processing, aluminum or aluminum alloy plate surface requirements are higher.

Ripple is generally made on brushing machine or erasing machine. Using the axial movement of the upper grinding roller, grinding brush on the surface of aluminum or aluminum alloy plate, the wave pattern is obtained.

Spinning grain, also known as optical rotation, is the use of cylindrical felt or stone nylon wheel mounted on the drilling machine, with kerosene and polishing paste, aluminum or aluminum alloy plate surface for rotary polishing obtained by a silk grain. It is mainly used for the decorative processing of circular signs and small decorative dial.

Thread is a small motor equipped with circular felt on the shaft, which is fixed on the table, and the edge of the table into an Angle of about 60 degrees, in addition to do a fixed aluminum plate pressure tea tray, paste a straight edge polyester film used to limit the thread degree of competition. Using the rotation of the felt and the linear movement of the drag plate, the surface of the aluminum plate is rotated to rub the thread pattern of the same width.

Characteristics of plastic electroplating Plastic electroplating products have the characteristics of both plastic and metal. It has small specific gravity, good corrosion resistance, easy molding, metallic luster and metallic texture, as well as electric, magnetic and welding characteristics. It can save complex mechanical processing procedures, save metal materials, and beautiful, decorative strong, at the same time, it also improves the mechanical strength of plastic. Due to the high stability of metal coating on light, atmosphere and other external factors, plastic metal plating can prevent plastic aging, prolong the service life of plastic parts. With the rapid development of industry, the application of plastic electroplating is becoming more and more widespread, and it has become one of the important means of surface decoration in plastic products. At home and abroad, it has been widely used in ABS, polypropylene, polysulfone, polycarbonate, nylon, phenolic glass fiber reinforced plastics, polystyrene and other plastic surface electroplating, especially ABS plastic electroplating is the most widely used, the best electroplating effect.